Valve Solutions For Corrosive Applications

Lined Ball Check Valve

Design Std

Manufacturer's Standard

Shell Design

ANSI B 16.34

Face To Face Dim.

ANSI B 16.1 UPTO 4">6" MFR'S

STANDARD

Flange Connection Rating

ANSI B 16.5 150# / DIN PN 10

Testing Standard

BS EN 12266-1

Connection

FLANGED, RF

Specifications

Ball Check Valve

Design Std

Manufacturer's Standard

Shell Design

ANSI B 16.34

Face To Face Dim.

ANSI B 16.1 UPTO 4">6" MFR'S STANDARD

Flange Connection Rating

ANSI B 16.5 150# / DIN PN 10

Testing Standard

BS EN 12266-1

Connection

FLANGED, RF

Lined Ball Check Valve Features

Product Features and Options Available

| TESTS PERFORMED | EN 12266-1 | EN 12266-1 |

|---|---|---|

| Sizes | 0.5"- 3" | 4"- 8" |

| High Pressure Shell Test Hydro | 225 PSI | 150 PSI |

| High Pressure Seat Test Hydro | 165 PSI | 150 PSI |

| Low Pressure Seat Test Pneumatic | 45 PSI | 45 PSI |

| SPARK TEST | KVDC |

|---|---|

| Testing Done At | 20 KDVC |

| MATERIAL | OPTIONS AVAILABLE |

|---|---|

| Castings | ASTM A 216 GR. WCB, ASTM A 351 GR. CF8 / CF8M, HASTELLOY C 276 / INCONEL |

| Lining Materials | PFA/FEP/ETFE/PVDF/PPH |

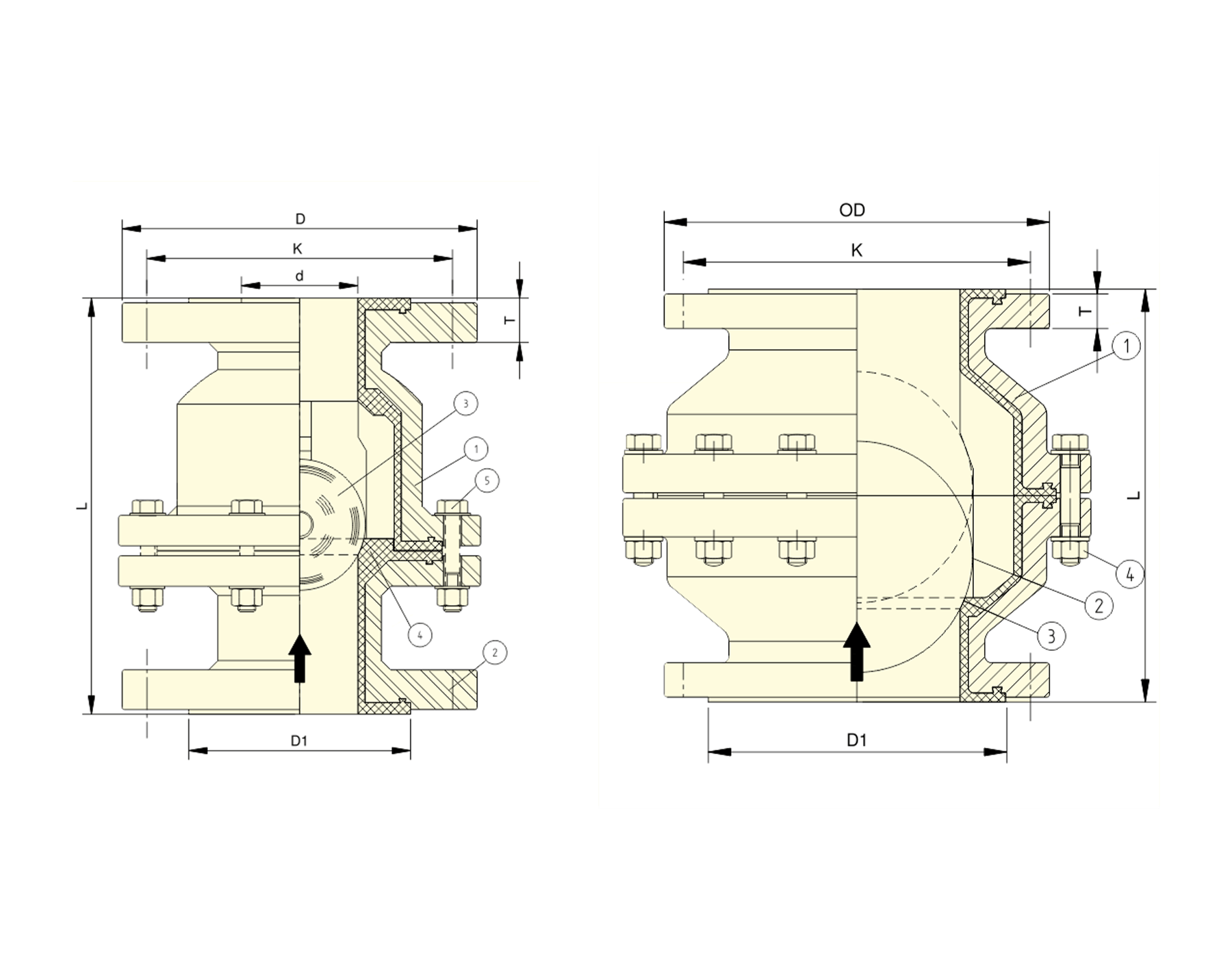

Part List

| PART NO. | DESCRIPTION | MATERIAL OF CONSTRUCTION | QTY. |

|---|---|---|---|

| 1 | Body | ASTM A 216 GR. WCB + PFA LINED | 1 |

| 2 | Side Piece | ASTM A 216 GR. WCB + PFA LINED | 1 |

| 3 | Ball | SOLID PTFE / TFM | 1 |

| 4 | Seat | INTEGRAL PFA | 1 |

| 5 | Fasteners | ASTM A 193 GR. B7 / 2H | 4-8 |

HOW TO READ VALVE CODE

| Code | BCKVC1T7L1XXF1SX02CODE | |

|---|---|---|

| Valve Type | BALL CHECK VALVE | BCKV |

| Casting | ASTM A216 GR WCB | C1 |

| Trim | PTFE | T7 |

| Lining Material | PFA | L1 |

| Seat | INTEGRAL PFA | XX |

| Fastener | STEEL PLATED | F1 |

| Operation | SELF OPERATING | S |

| Locking Arrangement | NOT APPLICABLE | X |

| Size | 2 | 2 |

Dimension Table

| Size (NB) | L ±.0.12 | d ±0.04 | D ±0.03 | D1 ±0.03 | T ±0.11 / -0.00 | K ±0.06 | ø | n | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | ||

| 0.5" | 4.25 | 108 | 0.49 | 12.5 | 3.54 | 90 | 1.38 | 35 | 0.47 | 12 | 2.36 | 60 | 5/8 | 16 | 4 |

| 0.75" | 5 | 127 | 0.7 | 19 | 4.25 | 108 | 1.69 | 43 | 0.59 | 15 | 2.71 | 69 | 5/8 | 16 | 4 |

| 1" | 5 | 127 | 0.9 | 25 | 4.25 | 108 | 2 | 51 | 0.59 | 15 | 3.11 | 79 | 5/8 | 16 | 4 |

| 1.25" | 6.49 | 165 | 1.2 | 32 | 5 | 127 | 2.51 | 64 | 0.74 | 19 | 3.5 | 89 | 5/8 | 16 | 4 |

| 1.5" | 6.49 | 165 | 1.49 | 38 | 5 | 127 | 2.87 | 73 | 0.74 | 19 | 3.86 | 98 | 5/8 | 16 | 4 |

| 2" | 7 | 178 | 1.96 | 50 | 5.98 | 152 | 3.62 | 92 | 0.8 | 20.5 | 4.76 | 121 | 3/4 | 19 | 4 |

| 2.5" | 7.99 | 203 | 2.55 | 65 | 7.51 | 191 | 4.13 | 105 | 0.98 | 25 | 5.51 | 140 | 3/4 | 19 | 4 |

| 3" | 7.99 | 203 | 2.95 | 75 | 7.51 | 191 | 5 | 127 | 0.98 | 25 | 5.98 | 152 | 3/4 | 19 | 4 |

| 4" | 9.01 | 229 | 3.93 | 100 | 9 | 229 | 6.18 | 157 | 0.98 | 25 | 7.51 | 191 | 3/4 | 19 | 8 |

| 6" | 11.9 | 303 | 5.9 | 150 | 11.02 | 280 | 8.5 | 216 | 0.98 | 25 | 9.48 | 241 | 7/8 | 22 | 8 |

| 8" | 16.7 | 425 | 7.87 | 200 | 14.6 | 373 | 10.6 | 270 | 1.1 | 28 | 11.7 | 298 | 7/8 | 22 | 8 |

-

A. Valve Net Weight

Size Ball Check Valve KGS LBS 0.5 2.15 4.8 0.75 3.7 8.2 1 3.7 8.2 1.5 6 13.2 2 9.8 21.6 2.5 15 33 3 20.7 45.6 4 28.4 62.5 6 59 129.8 8 95 209 -

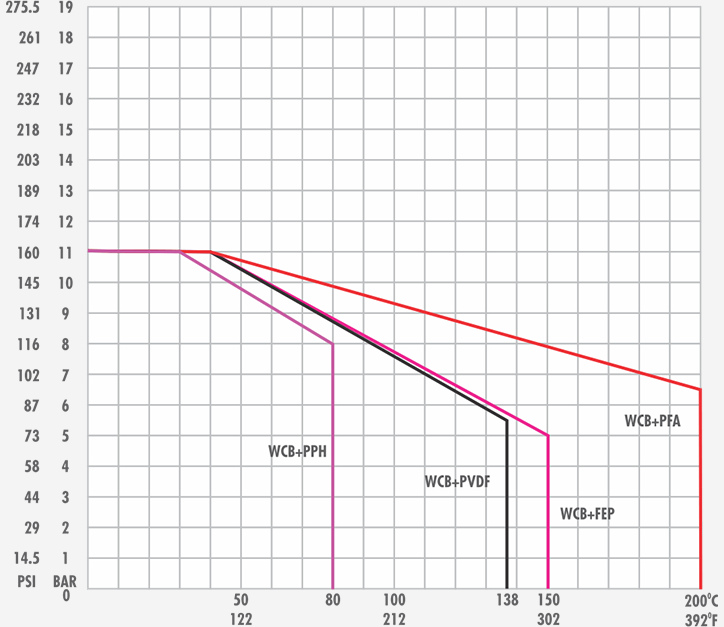

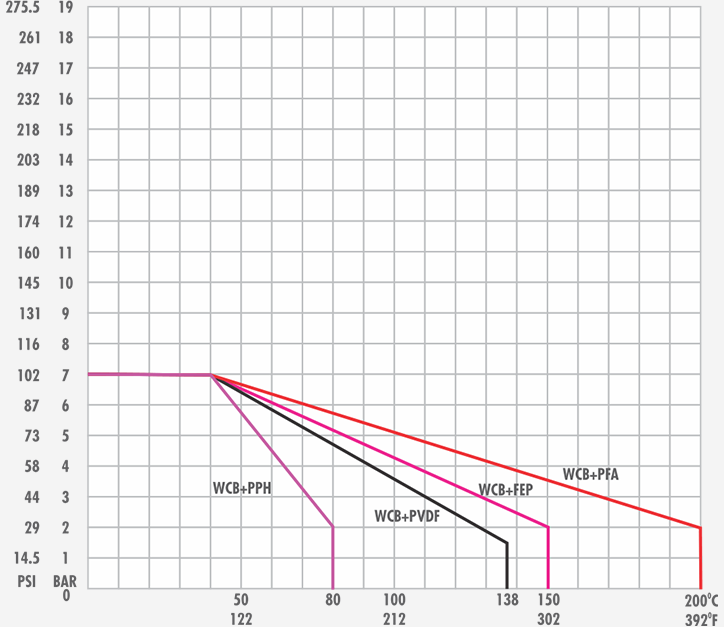

B. PRESSURE - TEMPERATURE GRAPH

Valve Code Used

VALVE TYPE CODE Globe Valve GLBV Ball Check Valve BCKV Swing Check Valve SCKV Sight Glass - Tubular/Full View SGFV Sight Glass - Double Window SGDW Sampling Valve - Flanged SMVF Sampling Valve- Sandwich SMVS Y Type Strainer YSTR TRIM INSERTS CODE ASTM A216 Gr WCB T1 ASTM A351 CF8 (SS 304) T2 ASTM A351 CF8M (SS316) T3 Alloy 20 T4 Duplex T5 Super Duplex T6 PTFE T7 PTFE + PVDF + EPDM T8 AISI410 T9 EPDM TE HASTELLOY C HC CASTING CODE ASTM A216 Gr WCB C1 ASTM A351 CF8 (SS 304) C2 ASTM A351 CF8M (SS316) C3 Alloy 20 C4 Duplex C5 Super Duplex C6 Hastelloy C C7 Glass GL LOCKING ARRANGMENT CODE YES Y NO N NOT APPLICABLE X SEAT CODE PTFE PT PTFE WITH SILICON PAD PS PTFE WITH VITON PAD PV TFM WITH SILICON PAD TS TFM WITH VITON PAD TV NOT APPLICABLE XX FASTENERS CODE STEEL PLATED F1 SS304 F2 SS316 F3 High Tensile F4 ASTM A193 GR B7 F5 BRASS F6 LINING MATERIAL CODE PFA L1 FEP L2 PVDF L3 ETFE L4 ECTFE L5 PPH L6 Antistatic PFA L7 OPERATION CODE LEVER L GEAR G BARE STEM B HAND WHEEL H SELF OPERATING S SIZE 0.5" 0.75" 1" 1.5" 2" 2.5" 3" 4" 5" 6" 8" 10" 12" 14" 16" 18" 20" 24" CODE 0H 75 01 1H 02 2H 03 04 05 06 08 10 12 14 16 18 20 24