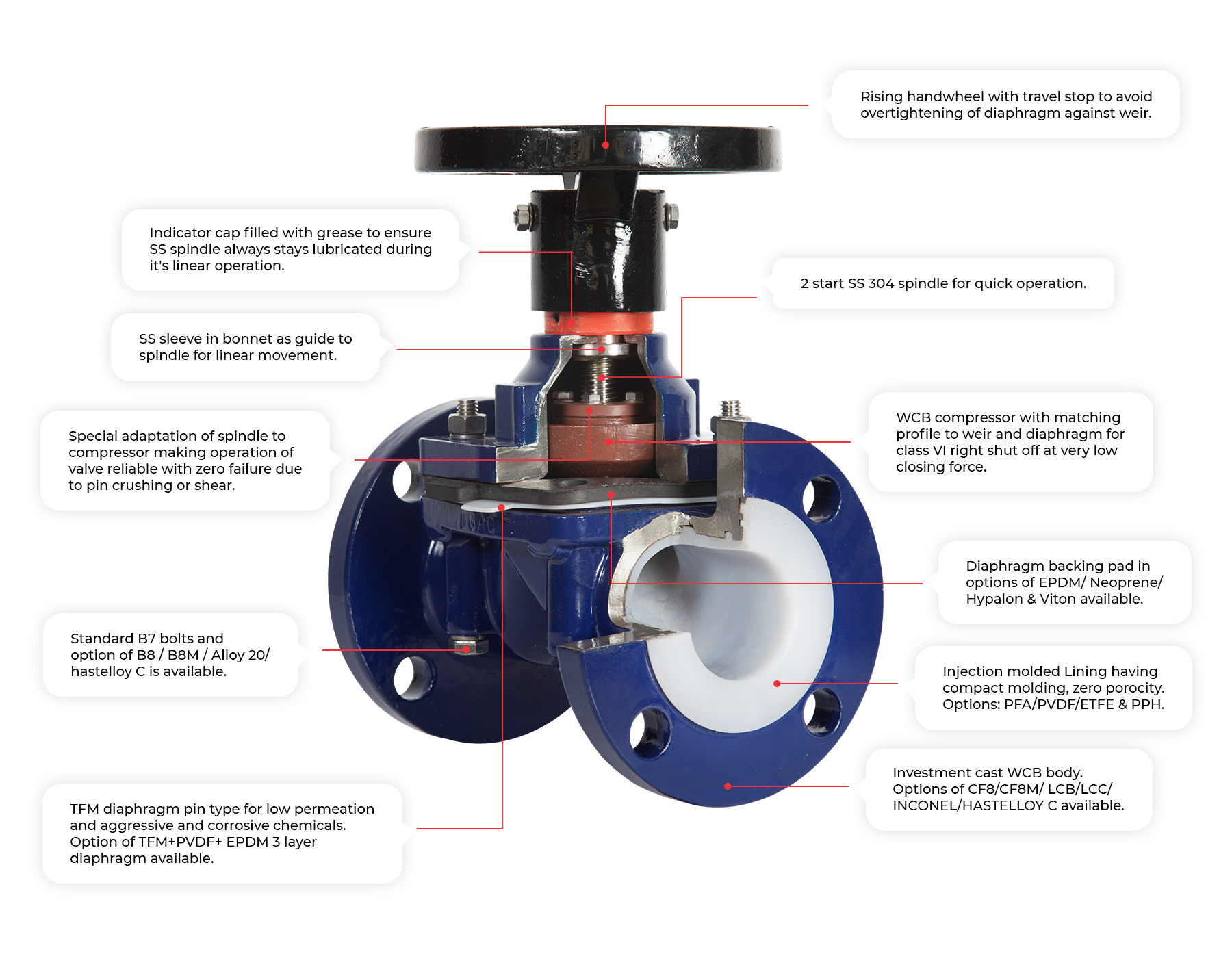

UNP offers both Rising Stem/Spindle & Rising Hand wheel design Diaphragm valves.

UNP offer regular (TFM + EPDM) double as well (PTFE+PVDF+EPDM) tripple layer Diaphragms to avoid failure of Diaphragm due to permeation especially for chlorine application.

UNP lining is anchored with dove tail groove and makes it’s valve suitable for both Pressure and Vacuum Applications.

UNP offers all metal components in investment castings, ensuring intact and homogeneous lining and having an overall even thickness of lining at intricate contours.

UNP uses virgin raw materials such as PFA from Dupont or Dyneon and specific grades are used which are high purity grade, enables use of it’s valves even in Pharma and food industries.

UNP can offer flange dimensions in DIN, ANSI and JIS standards.

UNP Valves are offered in manual, pneumatically & electrically actuated as well with modulating control feature.

UNP does lining of all Valves by latest injection molding process and not by transfer molding process makes its lining more compact and reliable.

UNP subjects it’s 100% valve quantity produced to both Hydro and Pneumatic Test ensuring 100% reliability for performance of valves under pressure.

UNP is an ISO 9001:2015 company and is having CE certificate for all its Lined Diaphragm valves design under PED 1128.

UNP provides all lining materials for corrosive applications such as PFA, FEP, PVDF, ETFE, ECTFE and PPH.

UNP standard body casting material is ASTM A 216 GR. WCB and upon requirement can also provide ASTM A 351 GR. CF 8 or CF 8 M / ASTM A 890 GR. 4A (CD3MN) / Super Duplex.

UNP provides Antistatic PFA lined Valves in grade C 980 of Dupont or 8502 ESDZ of Dyneon as just the grounding spring device can not conduct static charge from inside of the valve as normal grade of PFA is non-conductive liner in valve.